Advanced Airbag Restraint Systems

![[ OOP airbag deployment ]](/avg/pic/tc90.jpg) In 1996 reports were getting stronger that airbags were not the magic

protective restraint system some had hoped. In several moderate speed

collisions the airbag deployment caused serious injuries to a number of

short stature drivers and several children that were seated in the front

passenger seat.

As an intermediate step the National Highway Traffic Safety Administration

sanctioned the de-powering of airbags by changing the certification requirements.

The resulting airbags were some 30% softer than the first generation.

Furthermore, the NHTSA allowed the passenger airbag to be manually turned off

in case a rearward facing infant seat had to be placed in the front passenger seat.

Those measures addressed the immediate issues, but also reduced the overall

crash protection, afforded by airbags.

In 1996 reports were getting stronger that airbags were not the magic

protective restraint system some had hoped. In several moderate speed

collisions the airbag deployment caused serious injuries to a number of

short stature drivers and several children that were seated in the front

passenger seat.

As an intermediate step the National Highway Traffic Safety Administration

sanctioned the de-powering of airbags by changing the certification requirements.

The resulting airbags were some 30% softer than the first generation.

Furthermore, the NHTSA allowed the passenger airbag to be manually turned off

in case a rearward facing infant seat had to be placed in the front passenger seat.

Those measures addressed the immediate issues, but also reduced the overall

crash protection, afforded by airbags.

![30mph (50 km/h) crash [Man falling from three story building ]](/avg/img/manfallingfromthreestorybuilding.png) If a speed of 30 mph doesn't sound too serious, realize that it is the equivalent of falling

from a three story building onto the pavement. There aren't too many people that have fallen

from a three story building and lived to tell about it.

The airbag power needed to cushion this blow proved to be too much for short stature,

closely seated drivers and small children.

Those same airbags had, however, been remarkable successful in preventing the death of

occupants in high speed accidents, saving some 1200 lives per year.

If a speed of 30 mph doesn't sound too serious, realize that it is the equivalent of falling

from a three story building onto the pavement. There aren't too many people that have fallen

from a three story building and lived to tell about it.

The airbag power needed to cushion this blow proved to be too much for short stature,

closely seated drivers and small children.

Those same airbags had, however, been remarkable successful in preventing the death of

occupants in high speed accidents, saving some 1200 lives per year.

![25mph (40 km/h) crash [Man falling from two story building]](/avg/img/manfallingfromtwostorybuilding.png) The less powerful airbags, installed under the "depowered rule", could provide protection

to unbelted occupants only up to circa 25mph. That takes a whole story off the building.

With a national information campaign and "click-it-or-ticket" enforcement campaign the

government tried to increase the seat belt use rate, to prevent the measure from costing more

lives than it saved.

The less powerful airbags, installed under the "depowered rule", could provide protection

to unbelted occupants only up to circa 25mph. That takes a whole story off the building.

With a national information campaign and "click-it-or-ticket" enforcement campaign the

government tried to increase the seat belt use rate, to prevent the measure from costing more

lives than it saved.

While some research had shown that for a person, who was right on top of the airbag module,

only the strength or aggressivity of the inflator determined the injury risk, this was less clear

for a person sitting a mere 6 inches (150 mm) away from the airbag module.

Laboratory testing with the 5th percentile female dummy (height 5'0") showed that module design

and airbag fold could also play a role.

It was found that airbag modules that have a single piece cover increase the chance that the airbag

gets caught under the chin of a closely seated occupant. Once caught there, the force of deployment

would snap the head back with great force, increasing the risk of neck injury.

Single piece covers are often desired by vehicle stylists. Optimizing the airbag fold such that

the airbag deploys free from interaction with the occupant is an engineering challenge.

It is more difficult than with module designs that have a cover that splits through the center

which therefore have the engineer's preference.

![[ OOP deployment ]](/avg/pic/tc90-oop.jpg) If the bag is folded incorrectly, it may lock-up under the chin of a closely seated occupant

If the bag is folded incorrectly, it may lock-up under the chin of a closely seated occupant

An other challenge engineers face is the ongoing cost cutting to remain competitive. At less than $2 a set, airbag tethers are frequently targeted by the bean counters. Testing showed, however, that they are a worthwhile expense to improve airbag safety. Tethers are strips of fabric, hidden inside the airbag, that span from the back to the front of the cushion. They reduce the throw of the airbag during deployment and determine the final thickness of the cushion. Without such thickness control the airbag will expand into a spherical shape. The extra thickness increases the load on the head of a closely seated, short stature occupant. The head now has to pull the body rearwards which increases the neck loads.

![[ OOP deployment ]](/avg/pic/sd92-oop.jpg) Without tethers an airbag will balloon into a spherical shape.

Without tethers an airbag will balloon into a spherical shape.

![[ RFIS Warning ]](/avg/img/RFIS_warning.png) While the depowing of airbags and passenger airbag switch off feature delt with the pressing

injury risks, it did not eliminate all inflation induced injury risk, and put some classes of

occupants at risk, that had previously been protected. Then there were classes of occupants

that were not well protected by either system.

While the depowing of airbags and passenger airbag switch off feature delt with the pressing

injury risks, it did not eliminate all inflation induced injury risk, and put some classes of

occupants at risk, that had previously been protected. Then there were classes of occupants

that were not well protected by either system.

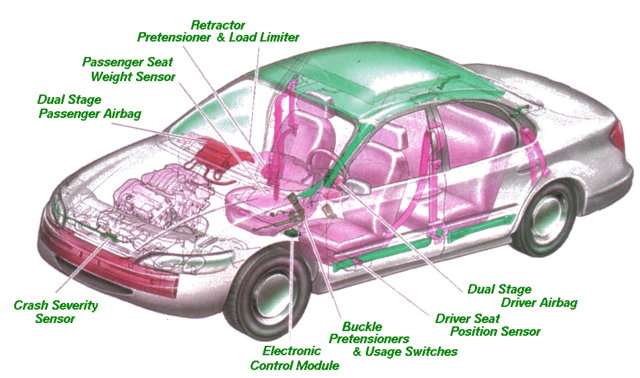

The industry went to work to gain back, what was lost. Bit by bit, new technologies were introduced. Dual threshold crash sensors; Dual stage inflators; Occupant classification sensors; Seat position sensors; Belt usage sensors; As well as pedal positioning and steering column adjustments that would allow a short driver to keep more distance from the steering wheel.

That may sound easier than it is. The crash of a vehicle driving at 30mph into a rigid barrier

only lasts about 100 milliseconds, or 0.1 seconds, which is less time than it takes to blink your eyes.

![[ Crash Event Timing ]](/avg/img/CrashEventTiming.png) The crash sensor only has about 15 to 20 milliseconds to determine that a crash is happening and whether

or not it is a severe one. By that time the vehicle may have only slowed down 2 mph (from 30mph to 28mph).

The crash sensor only has about 15 to 20 milliseconds to determine that a crash is happening and whether

or not it is a severe one. By that time the vehicle may have only slowed down 2 mph (from 30mph to 28mph).

No two crashes are alike. The vehicle has a totally different response whether it drives into

a tree or into the back of a truck. Often multiple sensors and sophisticated software algorithms

are needed to make the distinction.

![[ CRS with dummy ]](/avg/pic/CRSwithDummy.jpg)

- A crash sensor that can determine multiple levels of crash severity.

- A gas generator with a low and high output level, known as a dual stage inflator.

- A control module that can vary the timing between airbag stages.

- A seat belt usage sensor.

- A seat position sensor.

- A passenger seat weight sensor.

Seat belts have become smarter too. Pretensioners, activated by the crash sensors, take the slack out of the belt, making them more effective. Digressive load-limiters then limit and lower the belt force, as more belt material spools off the reel. That makes them work better in combination with the airbag. Bi-level load-limiter, can set the load levels higher or lower, depending on the size of the occupant. It takes its input from the amount of belt used by the occupant or from the seat position sensor, to gauge whether the occupant is small or large. A heavier occupant needs more restraining force than a smaller occupant under the same crash conditions (according to the old F = m x a) and fortunately usually also can sustain higher forces, before injuries occur.

With all this in place the restraint system can be tailored to the needs of the occupant. The airbag deployment strategy on the driver side might look like this:

| Belt Use | Crash Severity1 | Seat Position2 | -> | Airbag Deployment |

|---|---|---|---|---|

| yes | medium | forward | -> | none |

| yes | medium | rearward | -> | none |

| yes | high | forward | -> | none |

| yes | high | rearward | -> | low level deployment |

| no | medium | forward | -> | low level deployment |

| no | medium | rearward | -> | low level deployment |

| no | high | forward | -> | low level deployment |

| no | high | rearward | -> | high level deployment |

The airbag deployment strategy for the passenger side might look like this:

| Belt Use | Crash Severity | Occupant Weight3 | -> | Airbag Deployment |

|---|---|---|---|---|

| yes | medium | low | -> | none |

| yes | medium | high | -> | none |

| yes | high | low | -> | none |

| yes | high | high | -> | low level deployment |

| no | medium | low | -> | none |

| no | medium | high | -> | low level deployment |

| no | high | low | -> | low level deployment |

| no | high | high | -> | high level deployment |

These systems deal with the two most pressing problems:

- Avoid deployment of the passenger airbag if a child seat is placed there.

- Reduce the airbag deployment force for closely seated drivers.

Sensor accuracy (gray areas) and the realization that everything man makes

can fail, make that

the real deployment strategy is somewhat

more complicated than the one described above.

Sensors that can dynamically (i.e. during the crash) gauge

the distance of the occupant to the airbag module, have not been widely implemented.

These "proximity sensors" were foreseen by TOPSTM

to affect the airbag deployment in case the occupants are thrown out of position

prior to impact.

Fortunately the simulation analysis techniques caught up too, so that the interaction of the occupant with the deploying airbag can be studied. This helps the engineers balance the airbag strength between providing sufficient protection and minimizing injury risk.

![Driver Airbag Single Stage Deployment [ Driver Airbag Single Stage Deployment ]](/avg/anim/driver_airbag_single_stage_deployment.gif) |

![Driver Airbag Dual Stage Deployment [ Driver Airbag Dual Stage Deployment ]](/avg/anim/driver_airbag_dual_stage_deployment.gif) |

| Driver Airbag Single Stage Deployment Simulation | Driver Airbag Dual Stage Deployment Simulation |

Please direct questions regarding this page to airbags@hork.com

![HORK Enterprises [HORK]](/avg/img/HORKlogo148.gif)